Direct Injection Offers Time Savings and Flexibility

“This content was edited from the original article written by Robin Siktberg which appeared in the June 2018 issue of PrecisionAg Professional magazine”

One of the daily headaches applicators deal with on a regular basis — sometimes multiple times per day — is the need to flush out tanks and equipment between types of pesticides and herbicides. In recent years, weed resistance has made this chore more frequent. Farmers could put glyphosate in the tank and go from field to field, whether it was on corn or soybeans. Now, each field and crop may require a different herbicide, depending on the crop and the type of weed resistance. That means more time returning to home base and rinsing, mixing, and refilling the tank.

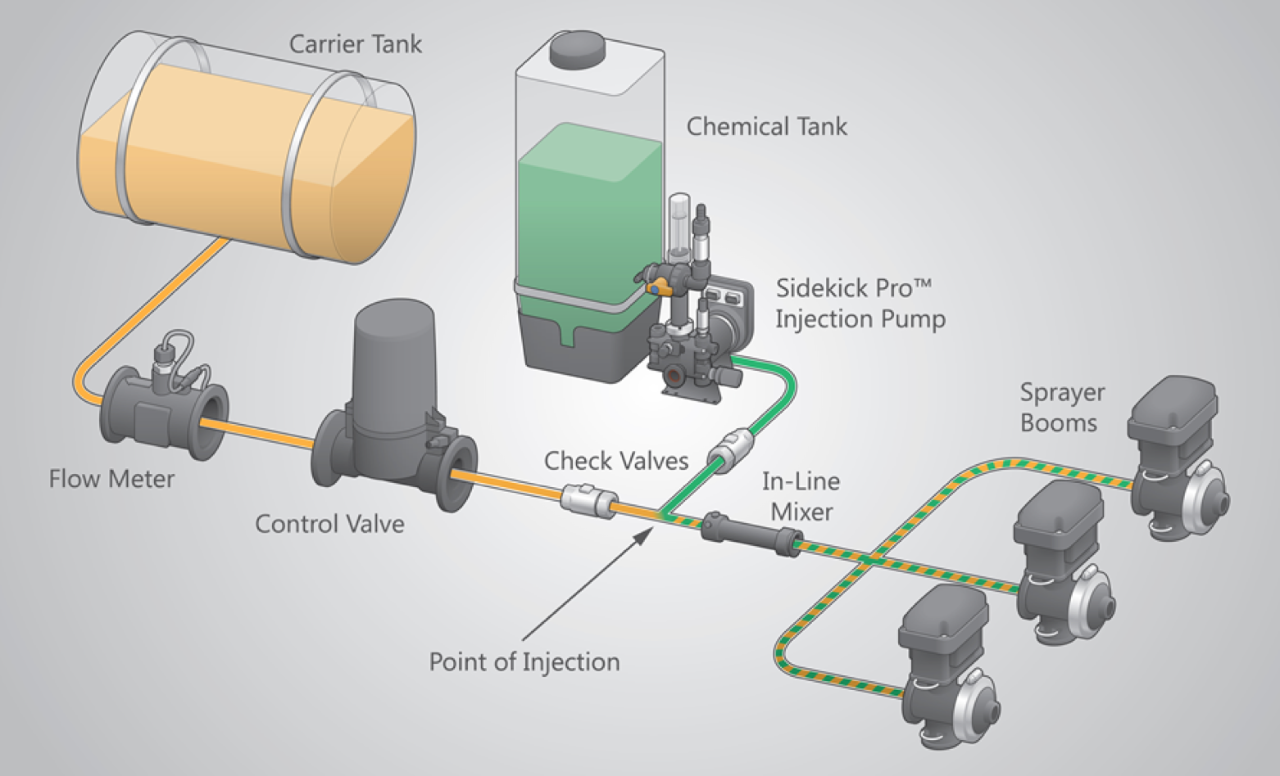

Direct injection can make life a lot easier by reducing time spent on these tasks. With direct injection, the pure liquid chemical is injected into the main stream of a liquid application. The tank is filled with water only, and the chemical is added as it is sprayed onto the field. Gary Esselink, Precision Ag Specialist/Product Manager at Raven Applied Technology, outlines a number of advantages direct injection systems have in today’s crop systems.

1. Greatly reduces risk of cross-contamination

Because the tank is only filled with water, there is no chemical residue to worry about. The booms and equipment such as end caps that are past the point of injection still need to be flushed, but eliminating the chance of residue in the tank is a big factor.

“You don’t have nearly as much to flush out,” Esselink says. “Some chemicals require triple rinsing, and not having to flush the tank is also a big-time savings. When using direct injection, many retailers reserve individual chemical tanks for certain products, so they don’t need to rinse in between.”

2. Less waste

Because the chemical is injected as it is used, there is no mixed product left over that needs to be sprayed out over the field or collected and disposed of at your facility. There’s also less contaminated rinse water, because you’re not rinsing the tank.

“This is a big advantage of direct injection,” says Esselink. “You save time, you save money, and it is safer for the environment.”

3. Application rates can be adjusted in the field

If one field has more weed pressure than another, direct injection can allow you to increase the amount of chemical being injected into the main stream. There’s no need to remix an entire tank. However, Esselink cautions that direct injection should not be used for variable-rate application or spot spraying because of the time needed for the chemical to reach the end of the boom.

4. Ability to easily adjust to adverse spraying conditions

Some chemicals, when mixed, need constant agitation or suspension while being applied. If weather conditions such as rain or wind delay the total emptying of the tank for a day, the remainder of the mixed chemical could settle.

“Fully re-agitating the settled chemical can sometimes be difficult,” Esselink says. “This can cause uneven distribution when the application is resumed, resulting in less-effective weed or pest control or crop damage. With direct injection there is no worry about mixed chemicals sitting in the tank when application is delayed.”

5. More accurate application and record keeping

Because the chemical is applied directly on a per-acre basis, it is easier to track the exact amount applied, both for efficacy and record keeping purposes. “Field records and data are becoming extremely important, and while you can be fairly accurate with a tank mix, with the Sidekick Pro we can be accurate to one-tenth of an ounce,” Esselink says.

6. Saves time when dealing with buffer zones

With some chemical applications, states are requiring buffer zones to reduce the risk of drift. That means one chemical is applied to control weeds on the perimeter of the field, and another on the main section. Esselink says some retailers are designating one sprayer for buffer zone applications. This saves time on having to clean out the sprayer, refill, and return to the field, but it still means two vehicles going to the same field.

“With direct injection, you could use two injection pumps for the two different chemicals and spray the buffer zone and the main section of the field in one trip,” Esselink says.

7. Extends life of anhydrous ammonia (NH3) equipment

Some nitrogen stabilizers used with NH3 can be quite corrosive to the metal parts on the application equipment.

By using direct injection, the nitrogen stabilizer can be applied just prior to the ground, and the exposure to metal parts in the system is greatly reduced.