How Precision Application can lead to better weed control

When it comes to keeping fields clean all season long, it’s important to note that one weed is one too many. Enter Operation Weed Eradication. The mission of this industry initiative is to educate growers and industry leaders on why the last weed standing is the strongest, most capable and the most genetically resistant weed on the farm, and ultimately, to provide a solution that secures the future state of farming.

This mindset for a weed-free future starts with a balanced approach between cultural best practices, eradication diligence, a knowledge of variables that could create setbacks throughout the season and last but certainly not least, chemical control.

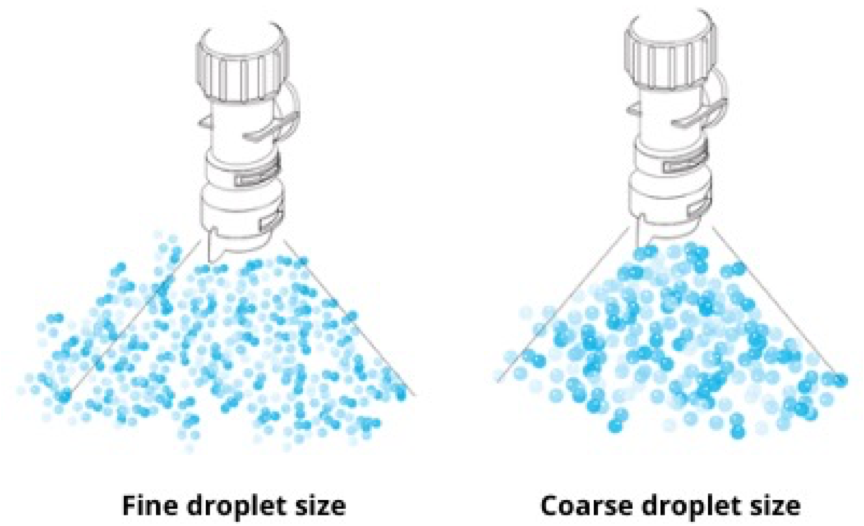

The truth is that pigweed resistance is driving the need for more effective and precise application of pesticides. Two major factors play a role in this: droplet size and application pressure.

Fine spray droplet size, usually less than 200 microns, remain airborne for an extended time, and are most prone to drift. The result is application to an area not intended to be treated. But too large of a droplet can either roll off the leaf or not have the coverage needed to take care of the pest.

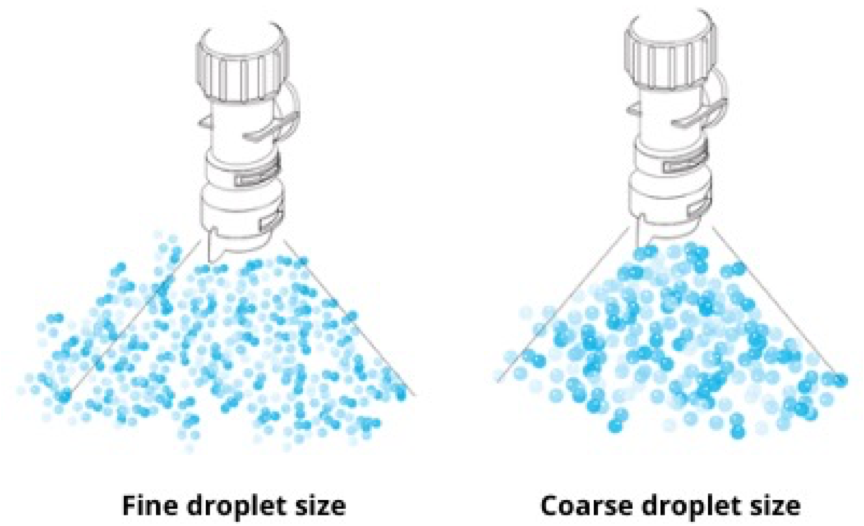

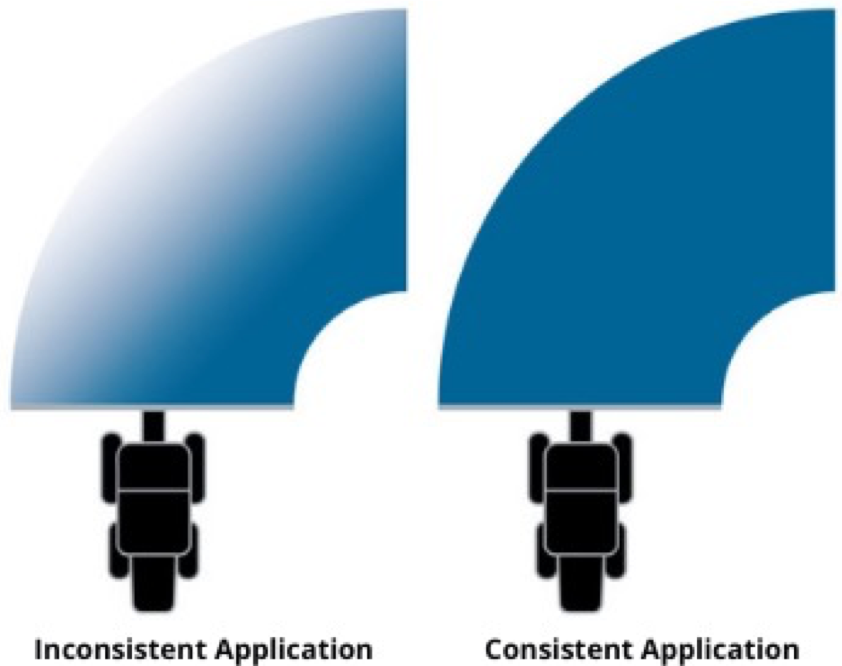

In addition to droplet size, issues can arise with conventional, flow-based spraying. Strictly flow-based spraying does not take into account boom pressure, which at lower and higher speeds, will impact spray pattern. Without turn compensation, you can over or under apply across the width of the boom, and under applying leads to less control and more pests.

Importance of Precision Application

Known for delivering impactful technology to farmers and custom applicators around the world, Raven Applied Technology does not shy away from helping to solve some of the biggest problems in the agriculture industry, including weed resistance.

A solution to this problem is pulse-width modulated, or PWM, valve technology. The PWM valve is attached to the nozzle body and controls the rate electronically, so the pressure doesn’t change according to the speed of the sprayer.

Correct and even boom height is also important in maintaining a consistent spray pattern, especially with the larger booms commonly utilized in today’s applications. Without correct boom height control, if the end of the boom is allowed to go too high, you may experience spray drift, if it goes too low, you will diminish the size of the spray pattern. Sensors measure the boom’s height from the ground, making adjustments to keep it level.

Some modern boom controls available in market, for example those offered by Raven, also have the ability to automatically shut off boom sections in point row situations and corners to ensure accuracy of rate and application in all types of fields.

Bottom line, consistent spray pattern is critical in ensuring total coverage of the field and a complete and thorough removal of weeds throughout the field.